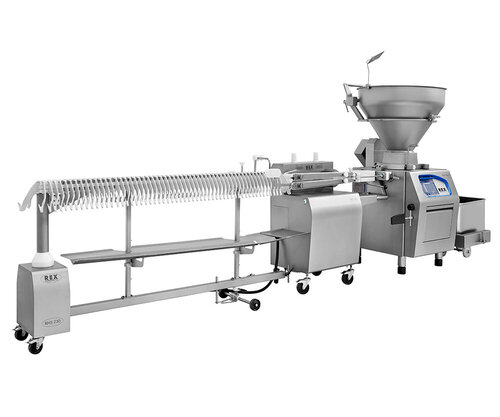

Advanced technology for the best mixing results in the meat and food industry

The most special feature here lies hidden inside: Mixer part and grinder part are completely separated from each other within the machine. During the first step, the entire material is mixed into a homogeneous mass with uniform quality. Then the product is conveyed from the mixer hopper and ground.

The mixer grinder is perfectly suited for the mixing and grinding of minced meat and cheese, the production of kebabs and hamburgers, use in meat standardization, as well as in raw sausage production.

- Separate mixer and grinding unit

- Dead-space-free mixing

- Hydraulic discharge flap for fast emptying of the mixer hopper

- Directions: Synchronous and reverse rotation in both directions

- Swivelling touch screen for flexible operation

- Highest hygiene standards

Details

Mixing capacity

700-900 Kg / 1000-1300 Kg

Hopper volume

1300 Liter / 1850 Liter

Meat screw drive

30 kW / 48 kW

Mixing shaft drive

2 x 13 kW

Feeder drive

1.5 kW

Voltage

-

Amperage

-

Length

3210 mm / 3830 mm

Width

1470 mm

Height

2530 mm

Weight

-